Roll-up doors are a common sight in industrial, commercial, and residential settings. These doors offer convenience, security, and space-saving benefits. However, behind their seemingly simple mechanism lies a complex system of components, each playing a crucial role. Among these components, bottom roller bracket assemblies among whiting door parts stand out as integral parts that ensure the smooth operation and longevity of roll-up doors.

Anatomy of a Roll-Up Door

Before delving into the significance of bottom roller bracket assemblies, it’s essential to understand the basic anatomy of a roll-up door. A typical roll-up door consists of slats or panels that roll up and down along tracks installed on the sides of the door opening. These panels are connected by hinges, allowing them to bend as the door rolls up or down. The entire system is powered by a motor and guided by various hardware components, including rollers, tracks, and brackets.

Function of Bottom Roller Bracket Assemblies

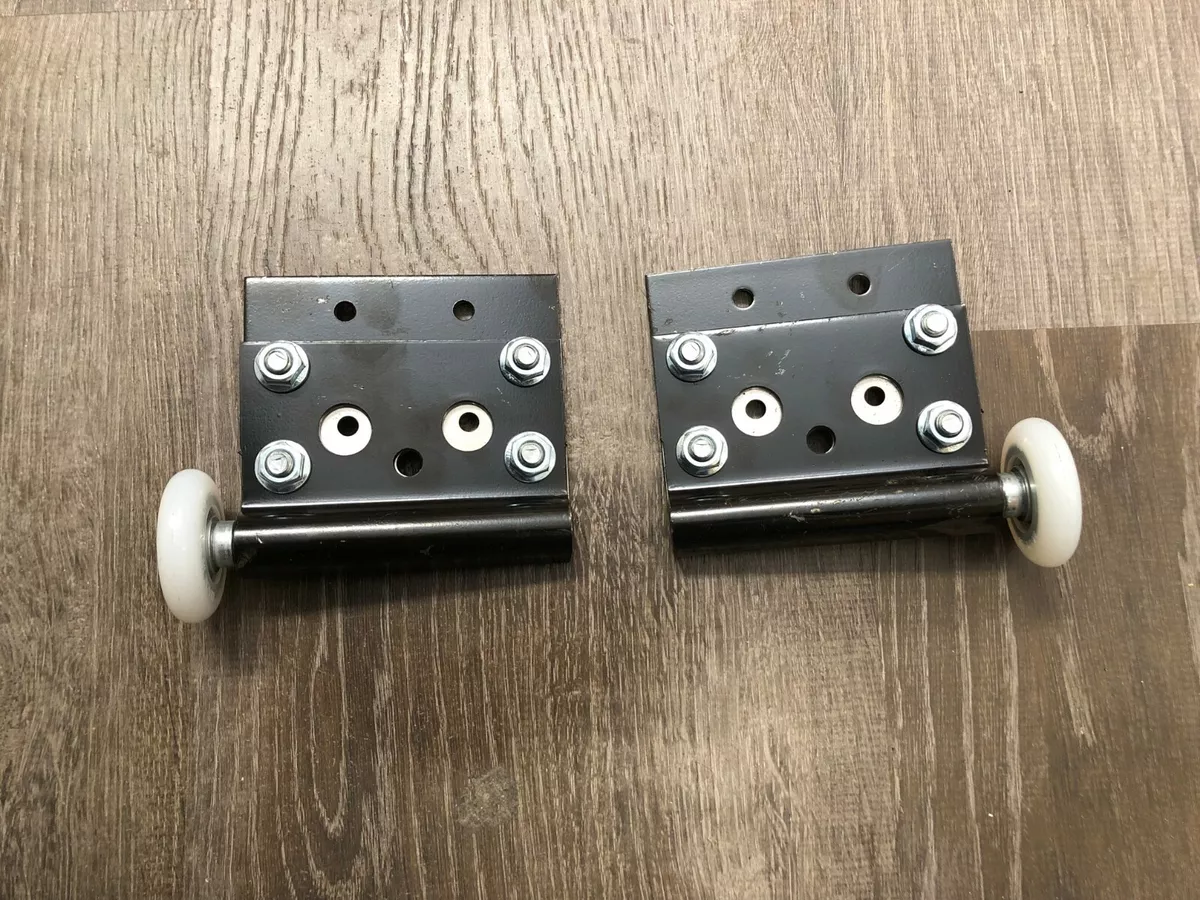

Bottom roller bracket assemblies serve as critical components in the operation of roll-up doors. They are attached to the bottom of the door panels and house the rollers that glide along the tracks. These assemblies provide support and stability to the door, ensuring smooth movement during opening and closing.

Key Components of Bottom Roller Bracket Assemblies

- Bracket Housing

The main body of the bottom roller bracket assembly, typically made of durable materials such as steel or aluminum. It provides a mounting point for the rollers and attaches securely to the bottom of the door panels.

- Rollers

These are the wheels that make contact with the tracks and facilitate the movement of the door. High-quality rollers ensure smooth operation and minimize friction, reducing wear and tear on the entire system.

- Axle Pins

Axle pins are used to secure the rollers within the bracket housing, allowing them to spin freely. Properly installed axle pins prevent the rollers from coming loose during operation.

- Bolts and Fasteners

Bolts and fasteners are used to attach the bottom roller bracket assembly to the door panels securely. They must be tightened properly to prevent any movement or instability.

Importance of Bottom Roller Bracket Assemblies

- Smooth Operation

Bottom roller bracket assemblies play a crucial role in ensuring the smooth operation of roll-up doors. By providing support and guiding the rollers along the tracks, these assemblies help minimize friction and resistance, allowing the door to open and close effortlessly.

- Stability and Balance

Properly functioning bottom roller bracket assemblies help maintain the stability and balance of the door panels. This is especially important for larger and heavier doors, as any imbalance or misalignment can lead to uneven movement and premature wear on the entire system.

- Durability and Longevity

High-quality bottom roller bracket assemblies are designed to withstand the rigors of daily use and harsh environmental conditions. By investing in durable components, property owners can ensure the longevity of their roll-up doors and avoid costly repairs or replacements down the line.

- Safety

Malfunctioning or damaged bottom roller bracket assemblies can pose a safety risk to users and property. Loose or broken rollers can cause the door to become jammed or fall off its tracks, potentially causing injury or property damage. Regular inspection and maintenance of bottom roller bracket assemblies are essential for ensuring safe operation.

- Reduced Maintenance Costs

By ensuring that bottom roller bracket assemblies are in good condition, property owners can reduce maintenance costs associated with roll-up doors. Routine inspections and timely repairs or replacements of worn or damaged components can help prevent more extensive damage and prolong the life of the door system.

Common Issues and Maintenance Tips

- Roller Misalignment

Over time, rollers may become misaligned due to wear and tear or improper installation. This can cause the door to operate unevenly or become stuck. Regular inspection and adjustment of roller alignment can help prevent this issue.

- Excessive Wear

Continuous use and exposure to the elements can cause rollers to wear out prematurely. Inspecting rollers for signs of wear, such as flat spots or rough surfaces, and replacing them as needed can prevent further damage to the door system.

- Lubrication

Proper lubrication of rollers and tracks is essential for smooth operation and reduced friction. Using a high-quality lubricant recommended by the manufacturer can prolong the life of bottom roller bracket assemblies and prevent corrosion.

- Tightening Fasteners

Bolts and fasteners securing the bottom roller bracket assemblies to the door panels should be checked regularly and tightened as needed. Loose fasteners can cause instability and compromise the integrity of the door system.

Conclusion

Bottom roller bracket assemblies may seem like small components, but their importance in the operation and longevity of roll-up doors cannot be overstated. By understanding their function and significance, property owners can take proactive measures to ensure that these critical components remain in optimal condition. Regular inspection, maintenance, and timely repairs or replacements are essential for safe and efficient operation of roll-up doors, ultimately saving time, money, and hassle in the long run.

Stay in touch to get more updates & news on Vents Magazine!